Natural stone is widely used in the decoration of architectural projects due to its unique texture, pattern and texture, which has made many buildings brilliant and distinctive.

As a natural building decoration material, stone has a unique decorative effect, but also has some of its own shortcomings, such as: cracks on the board surface, high water absorption, poor pollution resistance, and sand holes and holes on the surface. If these problems are not properly dealt with before the application of the stone, some hard-to-treat lesions will appear after application, which greatly reduces the decorative effect, and may even lead to the replacement of those diseased stones, resulting in an increase in process and waste of resources. How to ensure that the stone always presents the best decorative effect? This requires the coordination of the four parties of design units, construction enterprises, stone production enterprises, nursing companies, joint attention, and effective preventive measures and measures. We take natural marble as an example to talk about how to treat the surface of the stone to ensure that its surface is always beautiful.

▌Stone enterprise

1. Large board processing

The quality of the large stone slab plays a vital role in the presentation of the good decorative effect of the finished stone slab. It is so-called: the high-rise building is flat and the solid foundation is the first. The main factors affecting the quality of the stone slabs are the dry cracks, cracks and some fine holes between the stone textures, so the stone slabs must be repaired with an overall scraping glue.

In order to allow the surface glue to penetrate into the cracks and holes of the stone better, one is to heat the large board to 50 ℃ to let the cracks and capillaries of the stone be fully released; the second is to choose a low viscosity, good permeability epoxy resin Glue, so that it can fully penetrate into the open cracks and capillaries of the stone, and repair the large board from top to bottom. The use of epoxy resin adhesive for the treatment of dry and cracked stone is better than unsaturated resin adhesive, because epoxy resin adhesive has the characteristics of high bonding strength, low shrinkage and strong permeability, which can ensure that the stone slab is at room temperature The cracks and holes in the bottom can be filled well, improving the strength of the plate itself. The large board treated by the epoxy resin surface infiltration process not only has high surface polishing quality, but also greatly improves the strength and yield of the board. Although the cost of this kind of penetration glue repairing process is relatively high, it is very small compared to the benefits brought by the increase in the yield of large plates, and the stone production enterprises benefit more.

2. Specification board cutting and protection

When cutting the specification board, avoid contact with oil, acid and alkali substances that pollute the stone. The cut specification board is rinsed with water. White plates that are easily yellowed, such as Carrara White, Bianco Statuario, Ariston, and Volakas, are best washed with clean water to reduce the possibility of subsequent yellowing of the stone.

According to the construction drawings, the factory arranges the cut specifications boards to dry the stone, and the stone can be protected until the surface of the stone is dry until there is no clear water on the surface. For some sandstone materials and materials with high water absorption rate, it should be aired for at least 24 hours until the stone surface shows the original surface color before it can be used for protection. Factories are often unable to guarantee protection after the specification boards are completely dry due to processing time, restrictions on the layout site, and urgent project delivery. In this case, only water-based protective agents can be used for protection; if oil-based protection is used, it may be The moisture in the plate is sealed inside the stone, causing a chemical reaction between the moisture and the minerals of the stone to bury the hidden danger of discoloration of the stone in the later period, and there are water spots that affect the surface effect of the stone.

In addition, the factory should choose professional protection products according to the post-installation position and installation method of the specification board, such as: wet ground stone, the back of which should be protected with a two-component sealing protective agent to prevent the late wet paste materials. Water vapor enters the inside of the stone from the pores on the back to bury the hidden danger of the lesion; the front is protected with water-based antifouling agent, which can ensure that the water vapor inside the stone can be emitted, and at the same time can prevent the stone from being stained by the front during the transportation and pavement Invasion. The wall stone is coated on the six sides of the factory (sometimes on five sides. Some stones have been made with waterproof adhesive or resin adhesive + fiber mesh behind, in this case only five sides are waterproofed). Apply water-based antifouling agent, which can guarantee In the later installation, the colloid and the stone have good adhesion, and at the same time, it can avoid the pollution of the stone caused by external stains.

Brush protection agent should be applied twice or more times according to the water absorption rate of the stone, to ensure that the protection agent is evenly painted and the stone absorption is saturated; in addition, the protection agent must be given a certain curing period (not less than 24 hours), the protective agent is completely absorbed by the stone, so as to ensure the best protection effect.

After the above treatment, the stone was delivered to the construction site of the project and handed over to qualified construction units for installation.

▌Construction unit

1. Installation of wet ground stone

In the process of paving the stone, it is necessary to prevent the stone from breaking or shattering unnecessarily. If the stone that has been protected is cut on site, the newly formed cutting surface should be brushed with oily protective agent in time (it can not change the color of the stone, and the effect is fast) to avoid the moisture in the wet paste material from entering the stone from the newly formed cutting surface. The surface of the paved ground stone cannot be covered with a sealed protective film, and a breathable protective film should be used, and the protective film must not use materials that easily fade to prevent pollution of the stone.

2. Installation of facade stone

The installation of facade stone generally adopts glue paste and dry hanging installation. The adhesive used for point bonding and dry hanging should be a two-component epoxy structural adhesive, and the colloid must not contain solvents. If grooving or cutting on site, clean and dry the processed surface after grooving or cutting, and replenish the water-based antifouling agent in time. Because the back of the stone is protected by a water-based antifouling agent, it generally does not have an oil-proof function. If you choose a solvent-based epoxy structural adhesive, the hidden danger of oil leakage will be buried later.

▌Nursing company

1. Seam filling

After the paving and installation, the stone should be repaired, ground and crystallized before delivery. For example, the spliced seam needs to be cut on the paved and installed stone on site, and the cut parts should be brushed with oily protective agent in time (the color of the stone cannot be changed and the effect is fast), and then use a solvent-free two-component ring Oxygen adhesives are used to fill the joints (epoxy adhesive shrinkage is 0.1 to 0.5%, marble adhesive shrinkage is 2 to 7%; this is why some stone joints have black seams and negative edges).

2. Overall grinding

After the splicing colloid is completely cured (12 to 16 hours), use a grinder to grind from low mesh to high mesh in order to eliminate the cuts formed by the stone installation and the excess colloid at the joint. After grinding to 3000 mesh, use a vacuum cleaner to remove dust and moisture, clean the surface of the stone, and dry the stone as a whole. If necessary, the water-based antifouling agent can be re-applied as a whole (the protective agent before the factory will be worn out during the elimination of the cut and the overall grinding of the stone, especially the cut part, the protective effect before the factory will be reduced a lot, it is necessary Reapply the protective agent to the stone again. This will not increase the protection cost too much, but it can ensure that the decorative effect of the whole ground stone is durable and does not reduce the decorative effect due to grinding).

3. Crystal Care

The stone surface must be dried and cleaned before crystallization treatment. After the stone surface is completely dried, a crystal plane machine is used for crystallization treatment with the corresponding crystal hardener. Crystallization is to form a sealed transparent protective film on the surface of the stone. This layer of film needs to be superimposed multiple times to reach a certain thickness, so the crystallization of the stone should be carried out periodically.

▌Design unit

The design unit will make corresponding protection technical specifications and requirements according to the selection of stone materials. The technical requirements for stone protection should be specific and clear. If the back of the stone is wet-bonded, a two-component sealing protective agent must be used for film-forming protection; the water-based, water-proof, oil-proof and anti-fouling anti-fouling agent is used for protection on the front. The six sides of the facade stone must be protected by water-based, waterproof and anti-fouling protective agents. The protective agent must be applied uniformly and saturated, and the new surface must be applied in time when cutting the new surface.

After the above process, the decorative stone will definitely show the best decorative performance, and achieve the satisfactory results of the owners, design, construction, and stone suppliers.

For more information, you can consult cotrustone employees, or leave us a message!

Cotrustone in Marmomacc 2019, Verona, Italy

Cotrustone in Marmomacc 2019, Verona, Italy

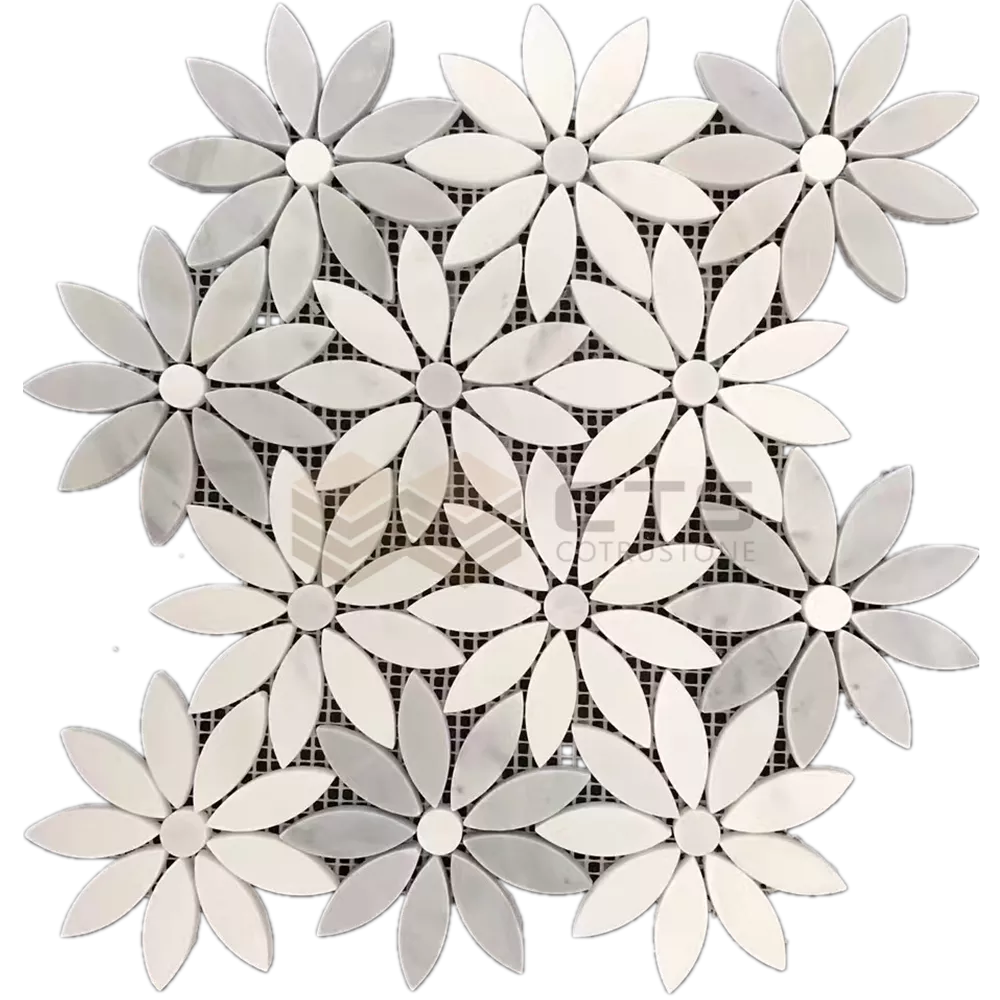

Mosaic in the world

Mosaic in the world